CONSULTING SERVICES

Our process ecosystem is based on real-time data exchange and optimize workflows that drive end-to-end accuracy and efficiency.

01

Pre Development + Planning

We offer tailored support to adapt your project to a modular approach or develop a new project from scratch. We conduct site surveys and modular test fits to ensure viability, along with providing preliminary cost estimates for optimal building massing. Partnering with us ensures a solid foundation for a successful modular construction project while still meeting developers pro-forma requirements of unit mixes and SQFT per unit.

4-6 Weeks

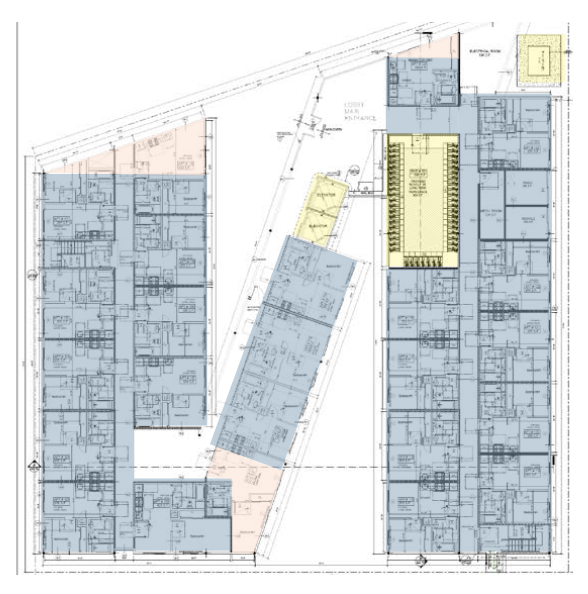

TYPICAL FLOORPLAN

PROPERTY ADDRESS

123 Main St

Somewhere, US 00000

SITE INFORMATION

ZONING

C2-1-CPIO

GROSS SITE AREA

12,620 SF

MAX ALLOWABLE HEIGHT

UNLIMITED

DESIRED FAR

3.8:1

DESIRED FLOOR AREA

48,500 SF

DESIRED DENSITY

87 UNITS

SITE PLAN NOTES

The overlay shown is an example of an efficient modular layout, minimizing modularity. WEST will optimize further for the unit mix, taking into consideration mateline work and other modular intricacies.

MODULAR CONSTRUCTION

CONVENTIONAL CONSTRUCTION

CURRENTLY NOT INCLUDED

MODULAR COST ESTIMATE

Overview

78

Number of Modules

(including staircases)

39,157

Total Modular Square Footage

$81,751

Cost Per Module

$162.85

Cost Per Square Foot

$6,376,629.65

Total Estimate Modular Cost

02

Pre Construction

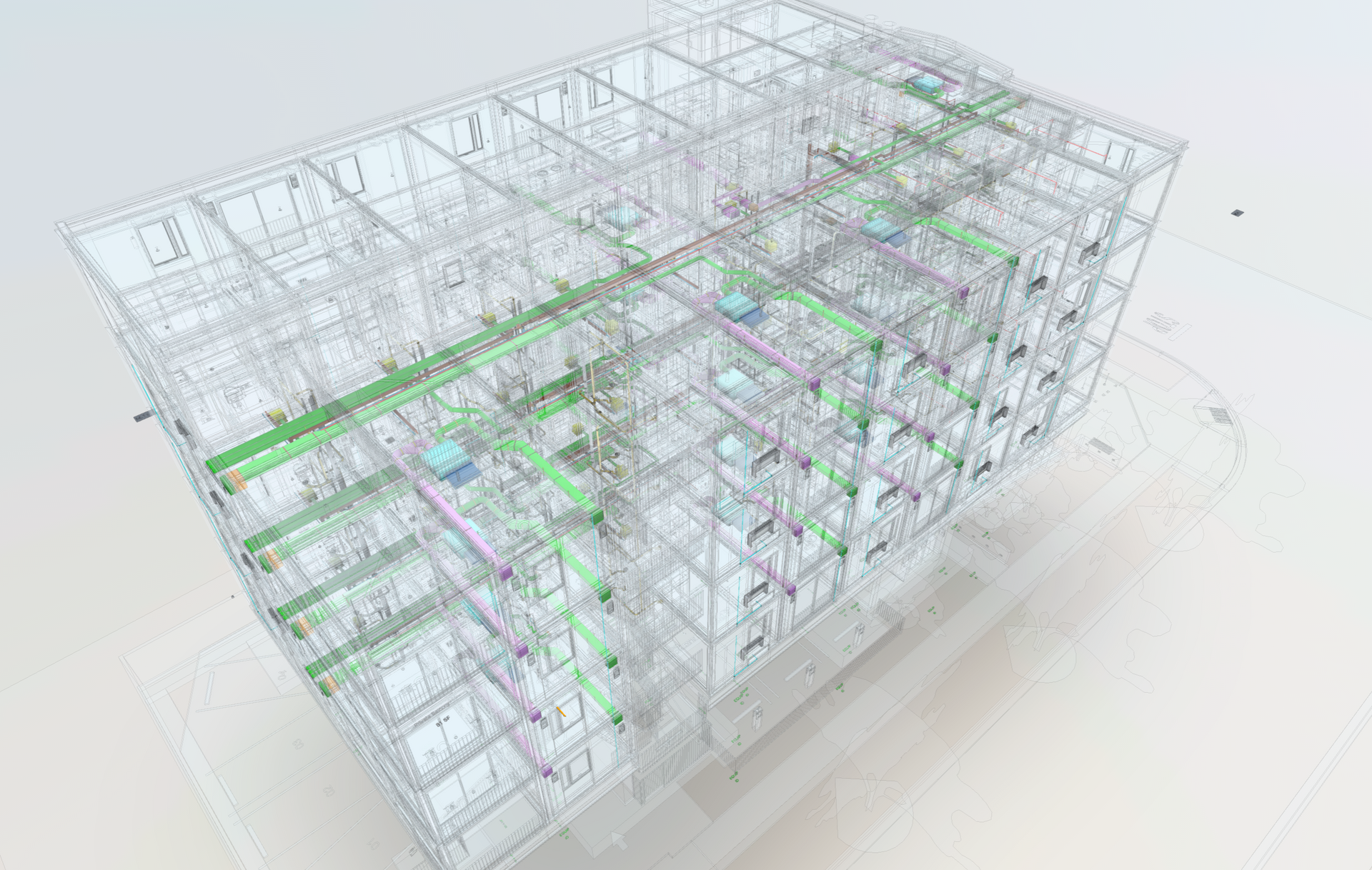

By 3-D modeling in BIM/REVIT software and creating a virtual twin we provide detailed quantity budgets and up-to-date Bill of Materials for onsite and offsite components. We also guide clients through responsibility and scope matrices, ensuring clarity. Additionally, we handle contract negotiations with General Contractors and subcontractors to secure cost savings, guaranteeing efficiency and quality.

4 Months

03

OPTIMIZED CONSTRUCTION DESIGN

With our modular architects and engineers, we optimize the design of your building for modular construction - identifying the most accurate budget for your specification on finishes and equipment. We also repurpose previous project engineering and design to streamline the process, saving clients time and money. We optimize workflows and share updates with you at every state of the process, using: Autodeck BIM 360 for real-time collaboration; BOM for detailed purchase plans; ERP for proper planning and cost control; and Revit for a design that exceeds the conventional.

3 Months

04

FABRICATION

Our manufacturing process consists on a total of 29 workstations, which are manufactured according to your requirements and inspected at each production line to guarantee their quality and code compliance.

3 Months

West Modular Manufacturing

3200 Paseo Village Way Ste 3528

San Diego CA 92130

West Modular Manufacturing Factory

Parque Industrial Cadena

Carretera Libre Tijuana – Mexicali Exterior Numero 22219, Interior B,

Colonia Fideicomiso El Florido

Tijuana, Baja California, Código Postal 22245

All Rights Reserved | West Modular Manufacturing

designed by idée.